The data reported in the “technical features/technical data sheets” refer to samples obtained in the perpendicular plane to the growth direction of the product during the reaction phase and not near the external surfaces. High resilience materials such as HR and AT must be previously subjected to mechanical treatments to generate cell breakage (mangling).

We recommend to obtain the desired details so that during the final use phase they are stressed in a parallel direction to the direction of growth.

Data and information contained in this document and in the each technical sheets are based on the knowledge available on the issue’s date or subsequent revisions. SITAB PE reserves the right to modify the data herein reported at any time.

SITAB PE does not guarantee the sufficiency of the recommendations/warnings contained in this document and in each technical data sheets. Furthermore it’s not excluded that further measures may be required in particular or exceptional circumstances.

In case of compressed materials it will be necessary a waiting time of at least 24 hours from the material decompression. The material must be kept compressed for the shortest possible time, ideally just for the time necessary for transport. In the 24 hours following decompression (or at least for a few hours) it is necessary that the blocks/plates are not subjected to pressure from any direction, such as load compression, blocks / plates stacked on one another or pressed against the wall. For viscoelastic materials it is necessary to consider their thermo sensitivity: the ideal temperatures should be higher than 15 degrees. It is also necessary that the support base is sufficiently smooth to allow the material to “slip”, thus facilitating the return.

Air Active

Incomparable comfort index

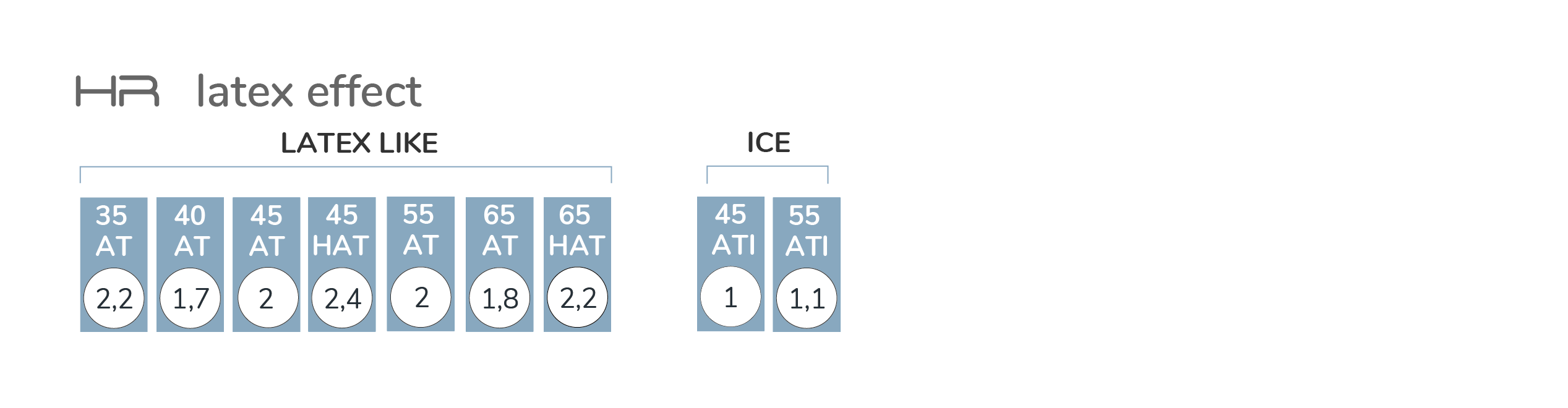

Air Active polyurethane foams, latex effect, reach a value of 3.0 equal to that of natural latex but with the advantage of a greater lightness.

Air Active products

Warnings

Air Active

Incomparable comfort index

Comfort index is extremely important as a high comfort index means that both stout and slim people will appreciate equally how a mattress or pillow can adapt to the shape and movements of their bodies.

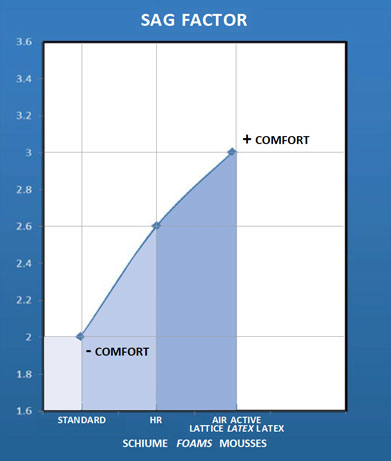

One of the fundamental elements to evaluate comfort is the Sag Factor, or comfort index, that measures the ratio between the compression values of foams at 65% and 25%. Conventional polyurethane foams have a Sag Factor value of about 2.0, while HR polyurethane foams show values of about 2.6.

Our AIR ACTIVE polyurethane foams, with their latex effect, reach 3.0, equaling natural rubber latex but keeping the advantage of a much greater lightness.

SAG FACTOR Test

All values result from experimental tests and provide an indication of the comfort index of each material: the higher the number, the greater the comfort.

GEL | refreshing effect

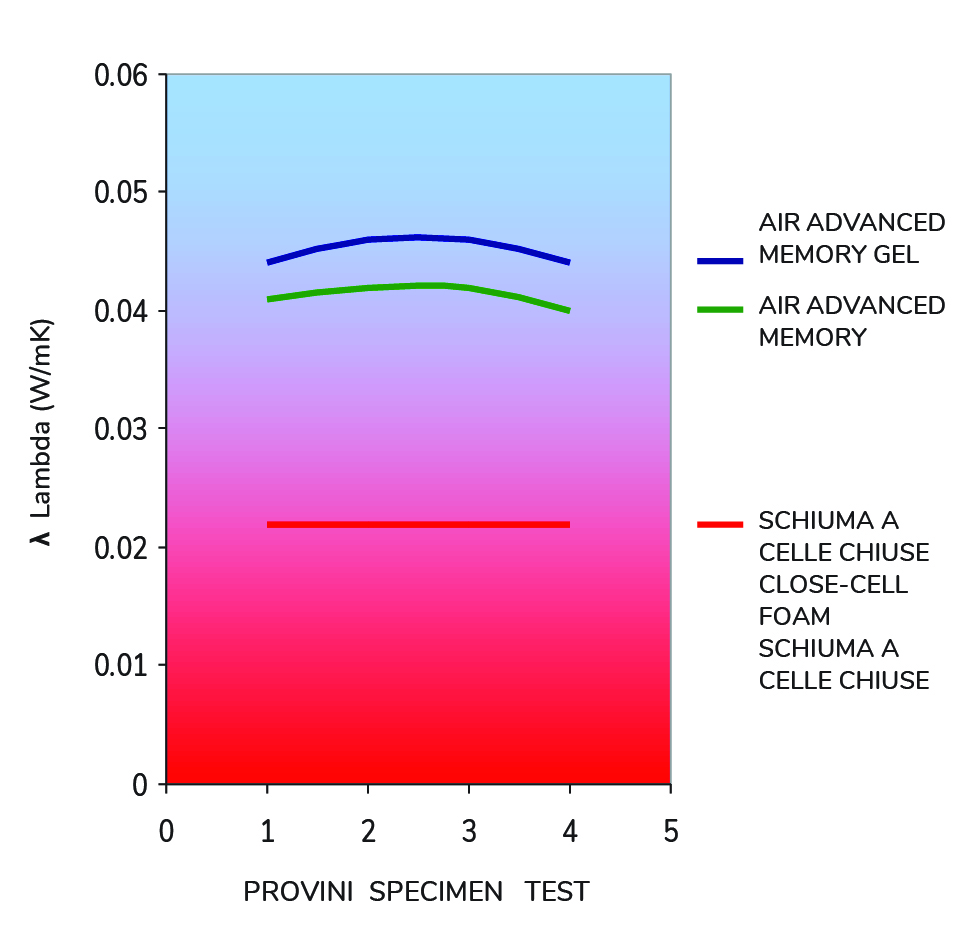

Thermal conductivity (shown by the symbol λ, lambda) measures the capacity of a given material to release heat. The greater the value λ, the better the heat dissipation of that material is.

In materials with a closed cell structure thermal exchanges occur principally by conduction through the solid walls of the cells and by radiation through the cells themselves, whereas in open cell structures they occur mainly by the convection between cells. It is therefore clear that in closed cell foams, as in traditional pneumatic viscoelastic ones, heat dissipation occurs very slowly. On the contrary, in innovative open cell foams such as AIR ADVANCED MEMORY GEL, the constant airflow optimizes heat dissipation by creating a beneficial refreshing effect.

The curves in the graph show how the dissipation of the heat occurs much more effectively in the open cell foams AIR than a normal closed cell visco foam. The test has been performed according to the UNI EN 12667 standard.

ICE | Comfort and freshness

From ongoing research on innovation and performances, SITAB developed ICE sensation, a comfortable and lasting feeling of freshness.

SITAB applied this special technology to the AIR MEMORY open cell polyurethane foams, the viscoelastic memory foam and AIR ACTIVE, the evolution of natural latex. Our new polyurethane foams – AIR MEMORY ICE, foam viscoelastic and AIR ACTIVE ICE with a latex effect – ensure a lasting and pleasant refreshing feeling thanks to their temperature-regulating control in the areas in contact with the body, thus creating and an ideal microclimate which allows a refreshing and comfortable rest. Thanks to their high degree of breathability and resilience, these foams are perfectly suitable for the manufacturing of anatomical structures for mattresses with top-level properties of comfort and freshness. The characteristics of the ICE formulation ensure innovative thermoregulatory performance that can improve the quality of sleep, greatly reducing the proliferation of bacteria and mold, guaranteeing a highly hygienic and comfortable product.